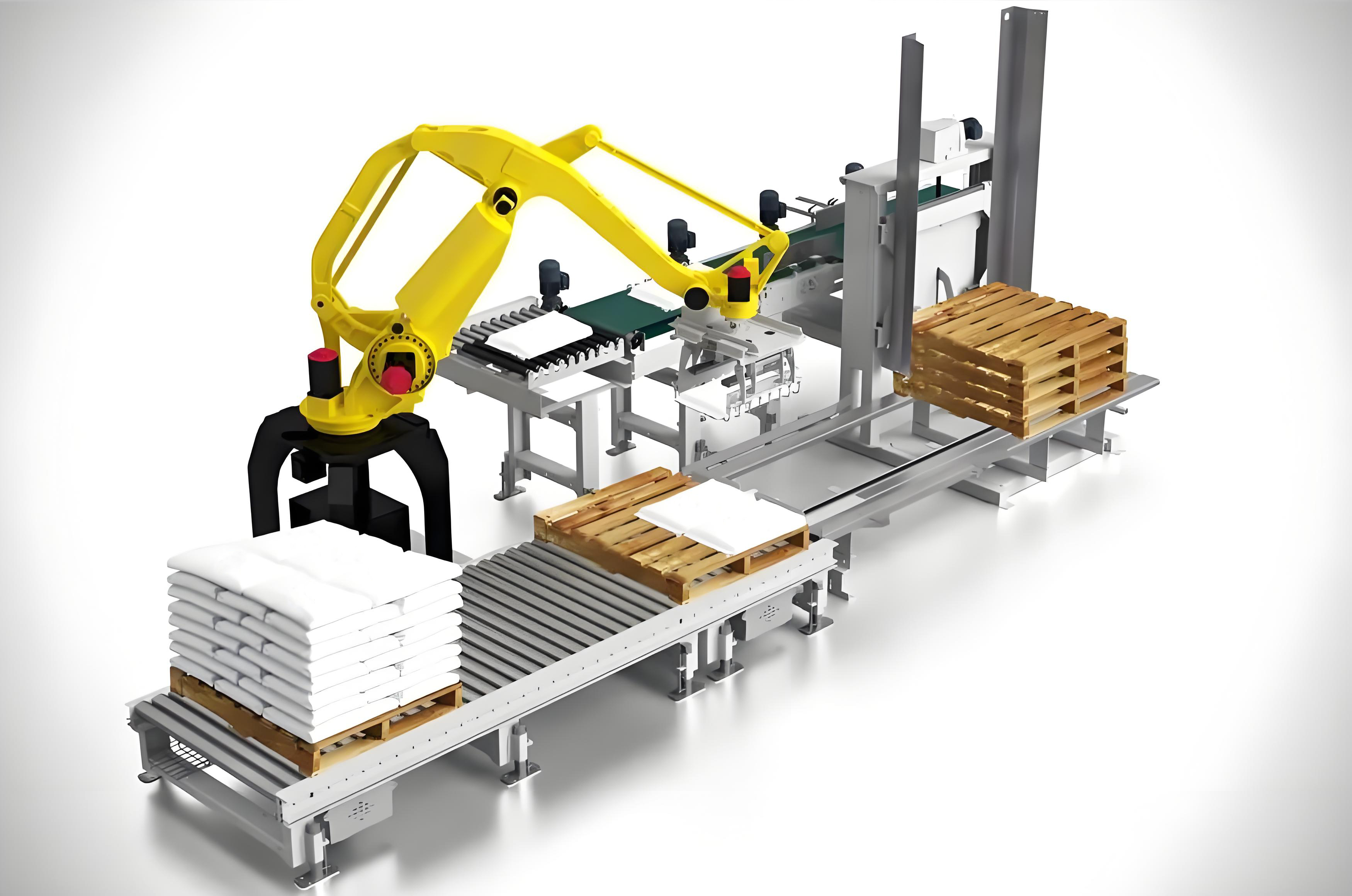

Automating the palletizing of bags using a robotic bag palletizer can provide one of the fastest returns on investment!

These systems use a palletizing robot arm to automatically stack bags, boxes, buckets, and more on pallets for shipping or storage. They can operate 24/7, effectively eliminating the need for a team of operators at the end of a packaging line stacking heavy bags on pallets. They are space saving solutions that can be oriented in any direction to accept bag inflow from a new or existing bagging system.

What types of bagging systems are good candidates for a robotic bag palletizer?

Typically, a bagging system that handles the fewest number of products, uses one type of bag, and requires at least 3,000 bags filled per 8 hour day is a good candidate for a robotic bag palletizer. Conversely, bagging systems with multiple products being packaged into paper and plastic bags could require more of a customized solution.