The grain packing machine, is also known as the grain filling and sealing machine. It packs and seals bags of various grains, such as rice, wheat, millet, corn, etc for storage or transport. A grain packing machine has three main sections: an infeed conveyor, where the product enters the machine; an outfeed conveyor, where the sealed bags leave the machine; and an elevator system that moves products from the infeed to the outfeed conveyor as they are packaged. Each grain packing machine is custom-built based on the needs of the facility in which it will be used.

Different types of grain packaging

In order to understand what a grain packaging machine does, it’s important to also know about how different types of grains are packaged. Grain storage is obviously necessary for crops that aren’t being used for food production. Some grains can sit in storage for a very long time and be perfectly fine but others like corn need to be packaged almost immediately. There are three main types of grain packaging: bulk, bagged, and boxed. Each type has its pros and cons and depending on what you’re storing as well as how long you plan on storing it will determine which one is best suited for your needs. Bulk storage takes place when there isn’t much capital available so sometimes growers buy smaller bins or bags that they then fill with grain themselves, whether by hand or with machinery.

Various grain packaging machines for sale

For different packaging needs, we offer various types of grain packaging machines for sale, including small grain packaging machines and large bag grain packaging machines. They have different functions and advantages.

# Small vertical grain filling and sealing machine

This is a small grain packaging machine designed for small batch production needs. In addition, it is an automatic packaging machine that can complete the packaging process of weighing and filling. Small grain packaging machines are very popular among small businesses. And the price of this grain packaging machine is absolutely affordable and favorable.

# Super efficient weigher machine for grains

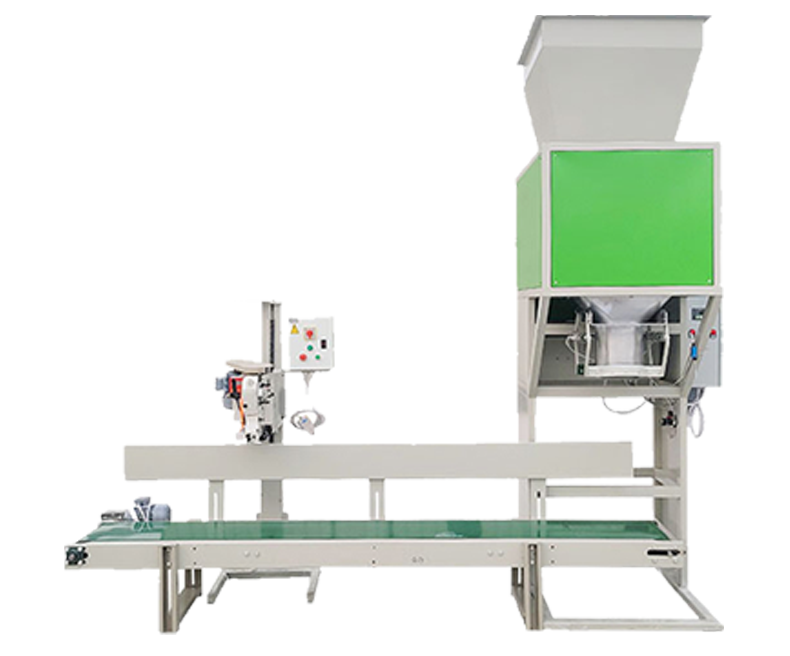

The automatic quantitative packaging scale has become the first choice for packaging in various industries with its "fast, accurate and stable" features. It adopts an integrated structure, small weighing capacity, compact structure, high efficiency, novel appearance, and easy installation and maintenance. The quantitative accuracy of the system is 0.2%. The packaging machine is mainly composed of four parts: the main machine (quantitative weighing, bag clamping, filling), the conveyor (with backrest), the column (adjust the height of the bag sewing machine according to the bag height), and the sewing machine.

Importance of Cereal Packaging Machines

Cereal packaging machines are essential for packaging cereals efficiently and stably. The machines are used for various packaging applications in the food, beverage and chemical industries. Depending on their application, cereal packaging machines come in various sizes with various features and options. They also have different bag sealing technologies, such as seams or heat seals. These features help users to package cereals neatly and consistently, thus providing consumers with fresh products while always maintaining hygiene.

Zhengzhou Yuheng Technology Co., Ltd. is a professional packaging machine manufacturer. We have been focusing on the design, research, manufacturing and marketing of various high-quality packaging machines for 15 years. If you have problems choosing a cereal packaging machine, please contact our experts for free purchase guidance.