Introduction of Multi-function Packing Machine

Multi-function packing machine is suitable for powdery and granular materials, such as grains, sand, feed, flour, flush fertilizer and granule fertilizer, additives, chemical products, coatings, refractory materials, glass slag and shaped blocks with diameters less than 50 mm within 40% of water content.

Adopting the active belt feeding mechanism will significantly reduce the blockage rate during the weighing process. It has simple operation, fast packaging speed, high precision and simple maintenance.

Working Process:

Manual bagging — Automatic filling — Automatic weight measuring — Automatic bag discharge — Automatic convey — Sewing — Next round

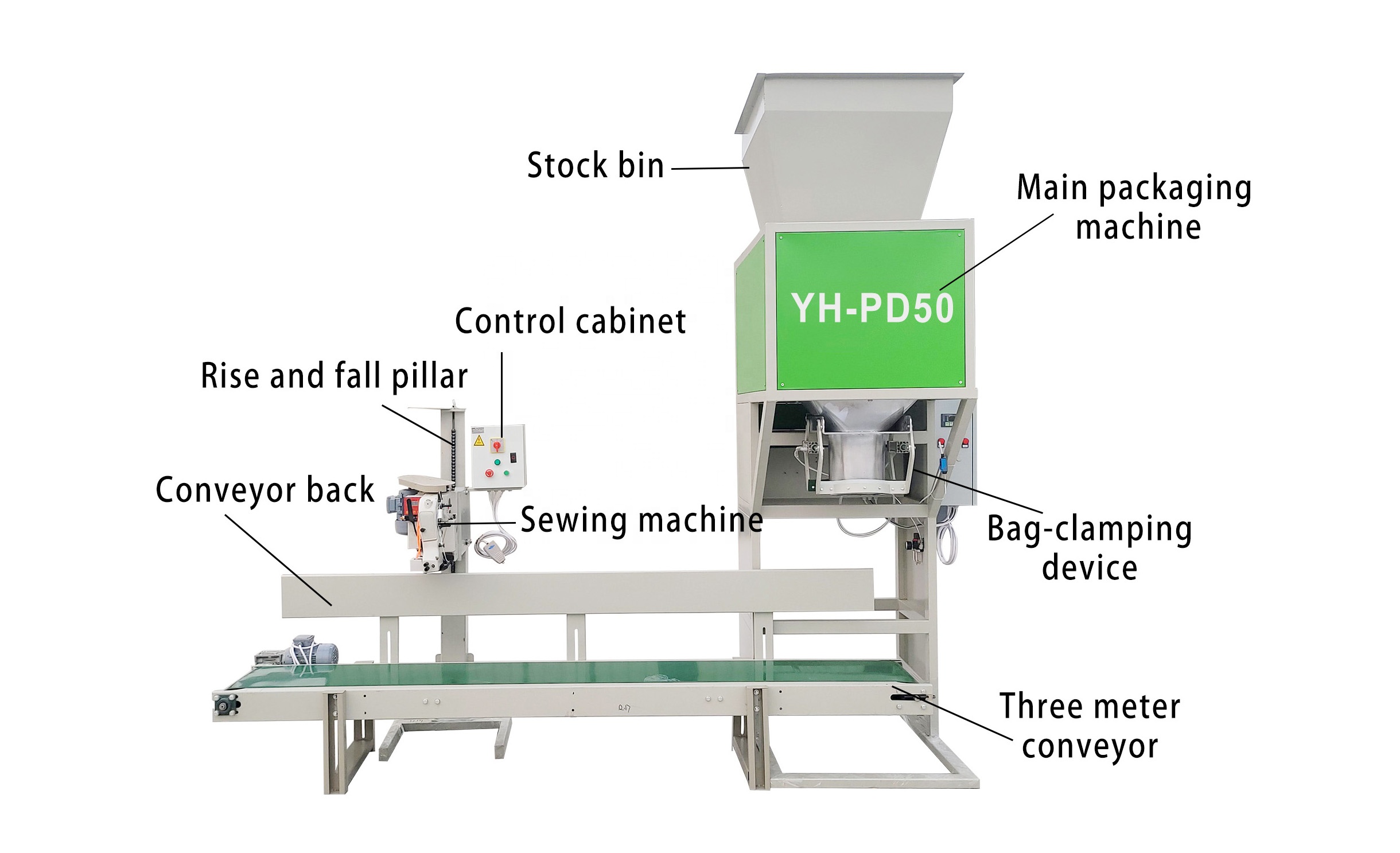

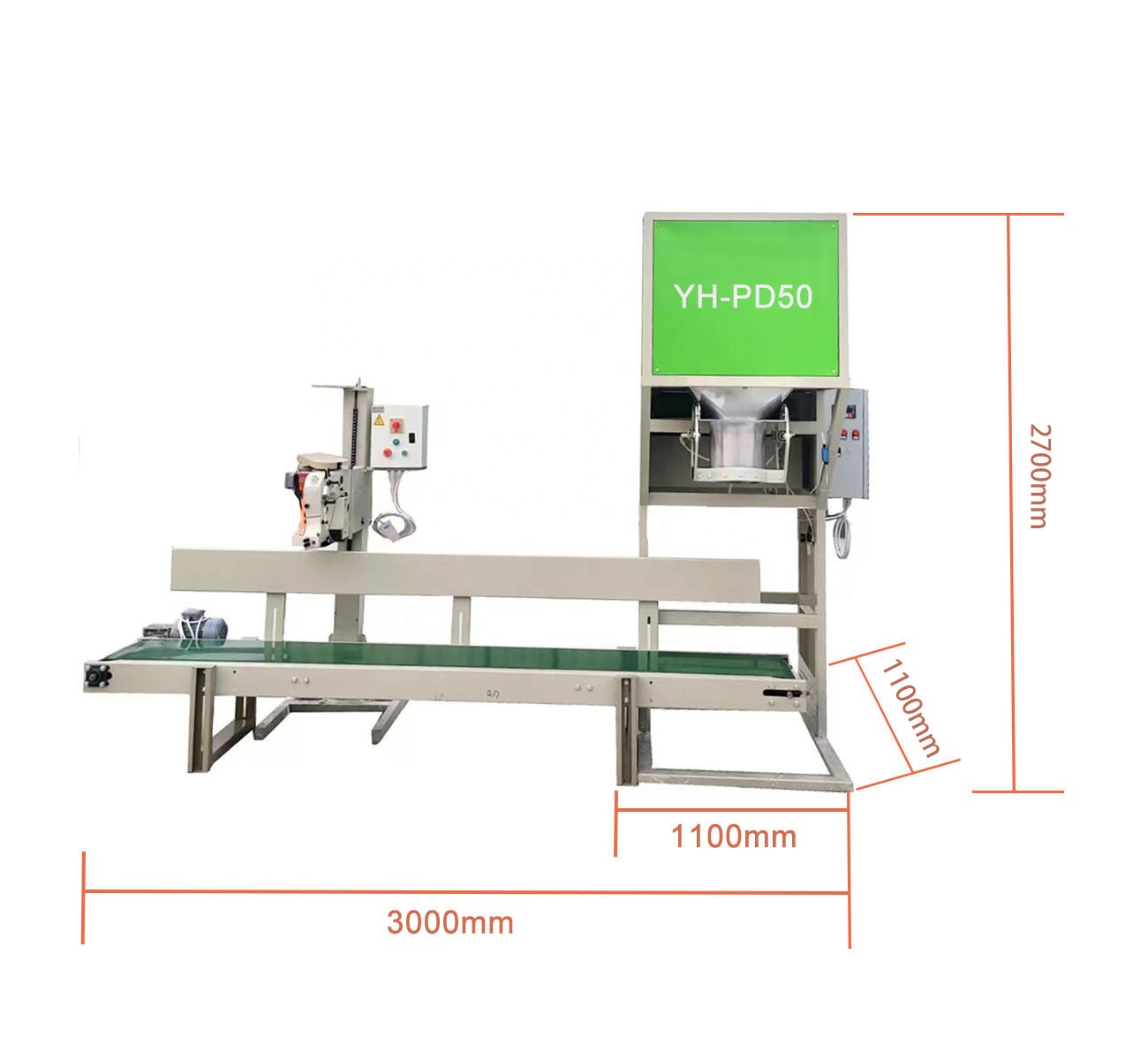

Structure of Multi-function Packing Machine

A computer-programmed control instrument with High measurement accuracy, stable performance, and digital display. Chinese, English and French languages. Automatic setting of control parameters, automatic drop correction, super differential alarm, fault diagnosis, etc.

The out layer of the machine adopts an electrostatic injection plastic process. The feed opening is made of smooth stainless steel, wear resistance, high fluidity, hygienic, corrosion resistance, and extended equipment service life.