Introduction of Pouch Powder Packing Machine

The 2-5kg pouch powder packing machine is used to fill powder into stand-up pouches, sachets and bottles. The filling quantity can be set by entering a certain amount or by using the filling weight. It can work with a conveyor belt or be used as an automatic machine to help you improve your work efficiency. It is widely used in the food, daily chemical and other industries.

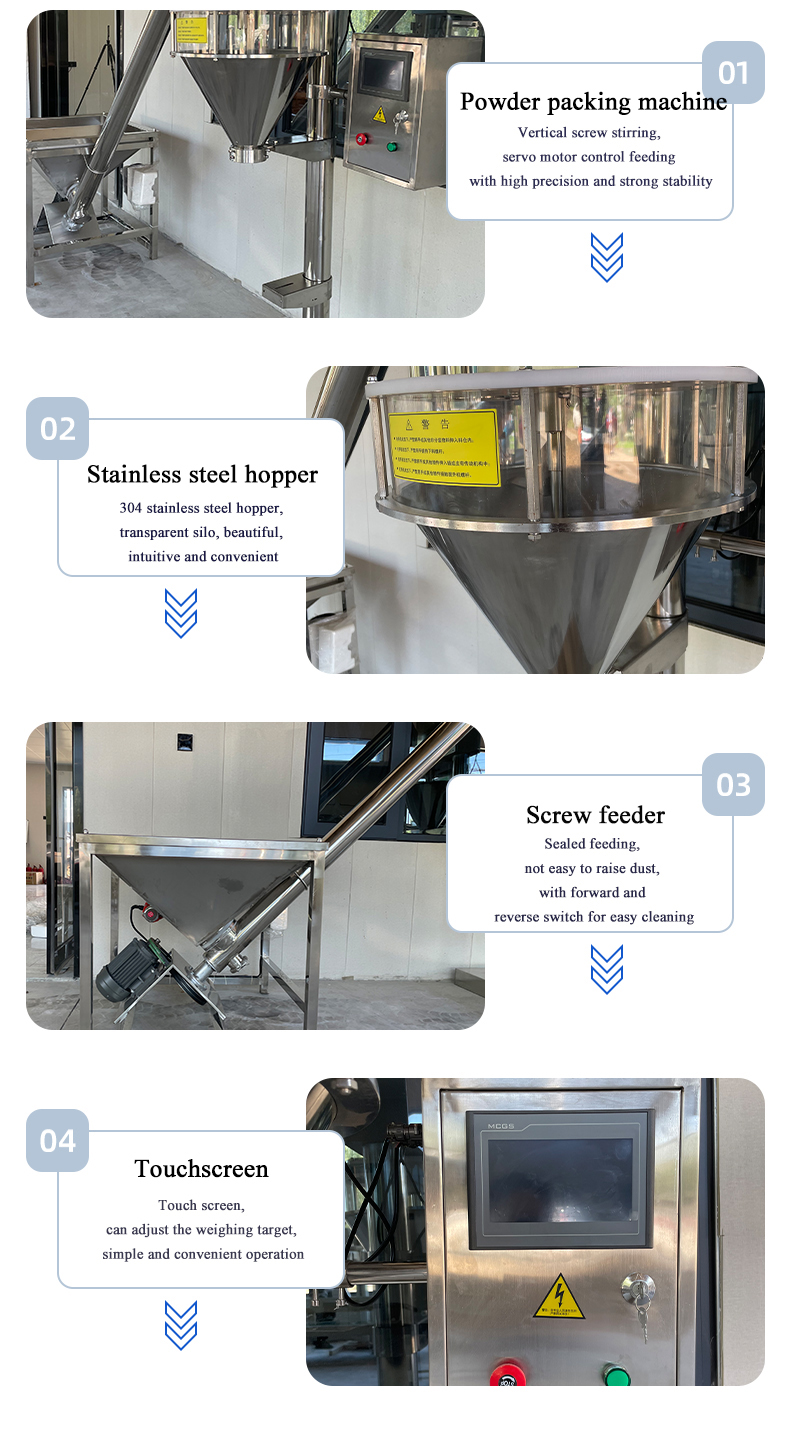

Structure of Pouch Powder Packing Machine

Applications of Pouch Powder Packing Machine

Applications: Milk Powder,Wheat Powder, Sesame Powder, Corn Starch, Flour, Chili Powder, Bean Flour, Coffee Powder, Chocolate Powder etc.

Product Feature of Pouch Powder Packing Machine

1. Adopt a stepping/servo motor and electronic weighing technology, the aircraft is slightly lower cost in comparison with the servo motor, and it is economical and practical. Spiral cutting, light-control technology

3. Scope: There is a certain fluidity of powder materials, containers (bags, cans)unlimited.

4. Materials due to changes in weight and material level of error correction can be automatically tracked. Photoelectric switch control, only manual bagging, bag clean, easy to seal. Screw feeder can be equipped with automatic feeding control.